అసమకాలిక గేర్డ్ ఎలివేటర్ ట్రాక్షన్ మెషిన్ THY-TM-YJ140

| సస్పెన్షన్ | 1:1 |

| గరిష్ట స్టాటిక్ లోడ్ | 2800 కిలోలు |

| నియంత్రణ | వివివిఎఫ్ |

| DZE-8E బ్రేక్ | DC110V 1A/AC220V 1.2A/0.6A పరిచయం |

| బరువు | 285 కిలోలు |

1.ఫాస్ట్ డెలివరీ

2. లావాదేవీ కేవలం ప్రారంభం మాత్రమే, సేవ ఎప్పటికీ ముగియదు

3. రకం: ట్రాక్షన్ మెషిన్ THY-TM-YJ140

4.మేము TORINDRIVE, MONADRIVE, MONTANARI, FAXI, SYLG మరియు ఇతర బ్రాండ్ల సింక్రోనస్ మరియు అసమకాలిక ట్రాక్షన్ యంత్రాలను అందించగలము.

5. నమ్మకమే ఆనందం! నేను మీ నమ్మకాన్ని ఎప్పటికీ వమ్ము చేయను!

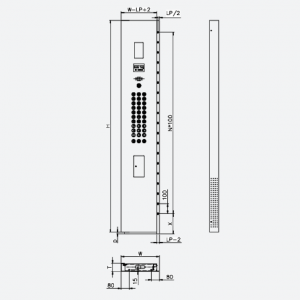

THY-TM-YJ140 గేర్డ్ అసమకాలిక ఎలివేటర్ ట్రాక్షన్ మెషిన్ TSG T7007-2016, GB 7588-2003, EN 81-20:2014, EN 81-50:2014 ప్రమాణాల సంబంధిత నిబంధనలకు అనుగుణంగా ఉంటుంది. ట్రాక్షన్ మెషిన్కు సంబంధించిన బ్రేక్ మోడల్ DZE-8E. వార్మ్ గేర్ రిడ్యూసర్ రకాన్ని ఉపయోగించి 400KG~500KG లోడ్ సామర్థ్యం కలిగిన సరుకు రవాణా ఎలివేటర్లకు అనుకూలం, వార్మ్ మెటీరియల్ 40Cr, మరియు వార్మ్ వీల్ మెటీరియల్ ZCuAl10Fe4Ni2Mn2. యంత్రాన్ని ఎడమ-మౌంటెడ్ మరియు కుడి-మౌంటెడ్గా విభజించారు మరియు ఇన్స్టాలేషన్ పద్ధతుల్లో నిలువు ఇన్స్టాలేషన్ మరియు క్షితిజ సమాంతర ఇన్స్టాలేషన్ ఉన్నాయి. ≥ 7.5Kw రేటెడ్ పవర్ ఉన్న మోటార్ల కోసం, బ్రేక్ ఒక ఉత్తేజిత పరికరంతో అమర్చబడి ఉంటుంది మరియు రేటెడ్ వోల్టేజ్ AC220V. వినియోగదారుకు సింగిల్-స్టేజ్ వోల్టేజ్ నియంత్రణ మాత్రమే అవసరం. ట్రాక్షన్ మెషిన్ వైర్ రోప్ యాంటీ-జంపింగ్ పరికరంతో అమర్చబడి ఉంటుంది. వైర్ రోప్ను ఇన్స్టాల్ చేసిన తర్వాత, వైర్ రోప్ మరియు యాంటీ-జంప్ పరికరం మధ్య దూరం 1.5mm మించకుండా ఉండేలా యాంటీ-జంప్ పరికరం యొక్క స్థానాన్ని సర్దుబాటు చేయండి. అసమకాలిక ఎలివేటర్ ట్రాక్షన్ మెషీన్కు వేర్వేరు ఇన్వర్టర్ల కోసం వేర్వేరు ఎన్కోడర్లు అవసరం మరియు కస్టమర్లు వారి స్వంత నియంత్రణ వ్యవస్థ ప్రకారం ఎంచుకోవచ్చు. ఇండోర్ పని వాతావరణానికి అనుకూలం.

ట్రాక్షన్ మెషిన్లో బ్రేక్ ఒక ముఖ్యమైన భాగం. బ్రేక్ యొక్క ఆపరేషన్ను క్రమం తప్పకుండా తనిఖీ చేయడం అవసరం. సాధారణంగా, తనిఖీ వ్యవధి ఒక నెల మించకూడదు. తనిఖీలు మరియు మరమ్మతులు చేసేటప్పుడు, మీరు వీటిని నిర్ధారించుకోవాలి:

1. అన్ని నిర్వహణ పనులు విద్యుత్ వైఫల్యం సంభవించినప్పుడు ఎలివేటర్ నిర్వహించబడుతుందని నిర్ధారించుకోవాలి మరియు ఎలివేటర్ అనుకోకుండా ప్రారంభించబడదని నిర్ధారించుకోవాలి;

2. బ్రేక్ సిస్టమ్ సర్దుబాటు సమయంలో, బ్రేక్ వీల్ లేదా మోటారుకు లోడ్ టార్క్ వర్తించదు;

3. తనిఖీ మరియు నిర్వహణ తర్వాత, అన్ని ఇంటర్కనెక్టడ్ మరియు లాకింగ్ భాగాలు లాక్ చేయబడ్డాయో లేదో తనిఖీ చేయండి మరియు ఎలివేటర్ వ్యవస్థ తిరిగి పనిచేయడానికి ముందు ఉపయోగం యొక్క అవసరాలకు అనుగుణంగా తగినంత బ్రేకింగ్ టార్క్కు సర్దుబాటు చేయండి;

4. అన్ని ఘర్షణ ఉపరితలాలు నూనెతో కలుషితం కాకూడదు.

బ్రేక్ యొక్క నిర్దిష్ట సర్దుబాటు పద్ధతి:

1. బ్రేకింగ్ ఫోర్స్ సర్దుబాటు: స్ప్రింగ్ను స్వేచ్ఛా స్థితిలో ఉంచడానికి ప్రధాన స్ప్రింగ్ ఎండ్లోని నట్ 1ని విప్పు, స్ప్రింగ్ గ్లాండ్ 2ని స్ప్రింగ్ యొక్క స్వేచ్ఛా చివరకి దగ్గరగా ఉండేలా చేయడానికి నట్ 1ని లాగండి, ఆపై తగినంత బ్రేకింగ్ ఫోర్స్ పొందడానికి నట్ 1ని సర్దుబాటు చేయండి.

2. బ్రేక్ ఓపెనింగ్ గ్యాప్ సర్దుబాటు: బ్రేక్ను శక్తివంతం చేయండి, బ్రేక్ షూ 3 మరియు బ్రేక్ వీల్ యొక్క రెండు ఆర్క్ ఉపరితలాల మధ్య అంతరాన్ని కొలవడానికి ఫీలర్ గేజ్ని ఉపయోగించండి, తద్వారా బ్రేక్ షూ మరియు బ్రేక్ వీల్ యొక్క రెండు ఆర్క్ ఉపరితలాల మధ్య అంతరం 0.1-0.2mm (సూత్రప్రాయంగా బ్రేక్ను తెరిచేటప్పుడు బ్రేక్ షూ మరియు బ్రేక్ వీల్ మధ్య ఎటువంటి ఘర్షణ లేదని నిర్ధారించుకోవడం మంచిది). ఓపెనింగ్ గ్యాప్ చాలా తక్కువగా ఉన్నప్పుడు, పరిమితి స్క్రూ 4ని సవ్యదిశలో తిప్పాలి, లేకుంటే గ్యాప్ పెరుగుతుంది. సరైన స్థానానికి సర్దుబాటు చేసినప్పుడు, స్క్రూ 4ని గట్టిగా లాక్ చేయడానికి నట్ 5ని ఉపయోగించండి. బ్రేక్ యొక్క ఐడిల్ స్ట్రోక్ అవసరాలకు అనుగుణంగా ఉందో లేదో మళ్లీ తనిఖీ చేయండి.

3. ఓపెనింగ్ సింక్రొనైజేషన్ సర్దుబాటు: పద్ధతి YJ150 మాదిరిగానే ఉంటుంది.